Tailoring The Screen For Your Project

Harkness projection screens are available either off the roll or with a bespoke finish. Depending on requirement, there are a variety of edge finishes.

Webbed with metal eyelets

50mm hemmed edge with a standard spacing of 15cm between eyelets, which allows for the most tension to be applied; non-reflective plastic eyelets are an option.

Velcro

Available in each black or white at 25mm or 50mm; the loop half of the Velcro can be welded to the screen.

Dual-Lock

Similar to Velcro, but attached with an adhesive backing, supplied for customer’s own frame.

Press Studs

Screen surface with studs to match those of customer’s own frame.

Black Plastic Webbing

Provides a border to the screen, prevents image bleeding.

Black Painted Masking

Provides a border to the screen, prevents image bleeding.

Webbed

A standard of 50mm hemmed edge

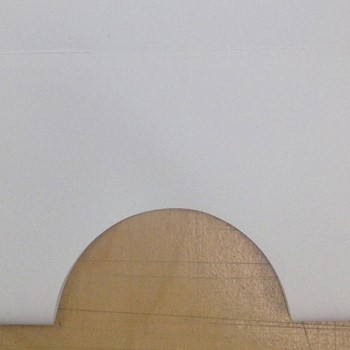

Pocket

Commonly used at the top to hang the screen to hang the screen from or the bottom for weight (bar/chain) to provide screen tension, but it can be on the sides if required. Scallop shaped cut outs for inserting a bar for tensioning or flying points.

Pocket And Skirt

Normally a 10cm lay flat pocket with a 20cm flap over the pocket for a ceiling to floor screen.

Cut Square

No edge finishing, cut to a specific dimension.

Cut Oversize

Ideal for stapling to a frame. Approximately 200mm additional; fabric on the height and width, dependent on panel widths.

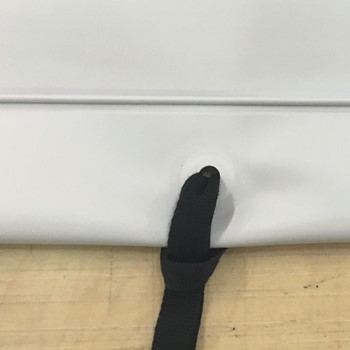

Keder

Commonly used at the top of the screen, Keder is ideal for bespoke frames and fast installations. Normally used with web and eye at the bottom of the screen.